See the Kinderegg effect in new technologies.

After testing the semi-closed system at its British Columbia facilities, Grieg Seafood will increase the use of the new technology at its Esperanza Inlet locations on the west coast of Vancouver Island in Canada.

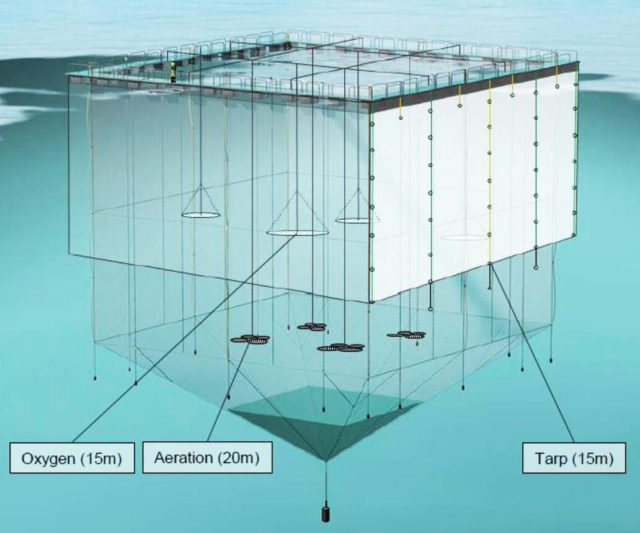

The new system, called “CO2L Flow”, allows the breeder to increase or decrease the degree of closure. This allows farmed salmon to benefit from the natural conditions of the sea, while providing protection for wild salmon, Grieg writes in a message.

The barriers can be lifted outside of wild salmon migration periods, so that localities can benefit from the temperatures, currents and oxygen levels of the sea. During his tests, Grieg recorded better growth, lower mortality lower, better feed conversion and reduced need for lice.

Improve

– As a company, we are always looking for new ways to improve our operations, which includes transitioning from standard agricultural equipment to completely new technology aimed at reducing the footprint of our operations, explains Rocky Boschman, regional manager of Grieg Seafood BC.

– This has several benefits, including preventing lateral interactions between wild and farmed salmon populations, protecting farmed populations from harmful algae, and allowing our farmers to better control water quality in the system using unique aeration technology.

– The system reduced the level of lice in the salmon during the trials, so the fish did not need lice treatment, says Boschman.

Three installations

– During periods of wild salmon migration or when there is algae in the water, the system’s barriers can be lowered, forming a barrier between wild salmon and hatchery stock, explains Dean Trethewey, director of marine production, certification and regulation of Grieg, in the message.

– This avoids lateral interactions and greatly reduces the transfer of salmon lice between stocks, explains Trethewey.

When the barriers are lowered, the system has technology that helps increase oxygen levels.

– Barriers can be completely lifted outside of these periods, so that farmed fish can benefit from natural sea conditions, temperatures, currents and oxygen levels, he says.

The company announced Feb. 8 that it would install the semi-closed system at its three farms in Esperanza Inlet, in time for the migration of young wild salmon in early 2023.

On January 14, representatives from Grieg Seafood BC, CPI Equipment, Poseidon Ocean Systems, Ozzo Technologies Canada and Fidelis Aquaculture gathered virtually to mark the signing of contracts to build the new system.

“Devoted reader. Thinker. Proud food specialist. Evil internet scholar. Bacon practitioner.”